Melba Kurman, author, and Hod Lipson, Cornell University associate professor in mechanical and aerospace engineering, are co-authors of “Fabricated: The New World of 3D Printing” (John Wiley & Sons, 2013) and leading voices in the field of 3D printing. They contributed this article to LiveScience‘s Expert Voices: Op-Ed & Insights as part of their new LiveScience series highlighting issues and developments in 3D-printing technology.

If you want to start a fight at a party full of people passionate about 3D printing, just mention technology patents. Immediately, people will stake out their positions and the room will erupt into chaos. Blogger Paul Banwatt sums up the debate nicely as a standoff between those “who believe that patents have held back 3D-printing technology and those who believe that patents have really incentivized innovation.”

Patents are like people. Some do good things and try to help others. Other patents behave like greedy bureaucrats by hiding behind rules and regulations and getting in the way of forward progress. Just to be clear here, in this article we’re not talking about the unresolved, looming battle over pirating or the 3D printing of unauthorized copies of IP (intellectual property)-protected designs. We mean patents on actual 3D-printing processes, tools and materials that are filed by companies that make and sell 3D printers and related technologies.

Constraints drive innovation

Patents drive technological advancement, but not in the way most people think. Conventional wisdom suggests that the temporary monopoly a patent gives a company enables that business to re-coup its earlier investment in the research and development (R&D) and attorney fees that generated the patent. When it comes to 3D-printing technology, conventional wisdom tells only a small part of the story. [The 10 Weirdest Things Created by 3D Printing]

Patents have helped 3D-printing technology advance, but not by giving a patent holder temporary control over a particular printing technology. Patents, particularly key patents on critical platform technologies, have pushed 3D-printing technology forward by introducing constraints. Patent-induced constraints force technological ingenuity — which, in turn, drives innovation. The reason several different 3D-printing techniques exist today is, in part, the constraints imposed by patents that blocked key technologies and hence required the creation of workarounds.

Vast, open expanses of technological green fields are nice. But as Amazon CEO Jeff Bezos put it, “Frugality drives innovation, just like other constraints do. One of the only ways to get out of a tight box is to invent your way out.” Bezos was referring to Amazon‘s early cash-poor days when, lacking a fat advertising budget, the company innovated around its constraints and eventually created its game-changing associates program.

Several innovative 3D-printing technologies are the fruit of patent-induced constraints. Over the past few decades, to play on the commercial battlefield, 3D-printing companies were forced to come up with technological workarounds to develop their own commercial 3D printers and related products. To avoid patent lawsuits, 3D-printing companies innovated their way out of a “tight box” by inventing around other companies’ technology patents. As rival companies navigated their way around patent-induced constraints, they invented yet more innovative technologies.

Innovation in the face of constraints

In this environment, nearly two-dozen novel and important 3D-printing technologies were invented as a direct or indirect response to somebody else‘s patents. [The Top 10 Inventions That Changed the World]

Here are a few examples:

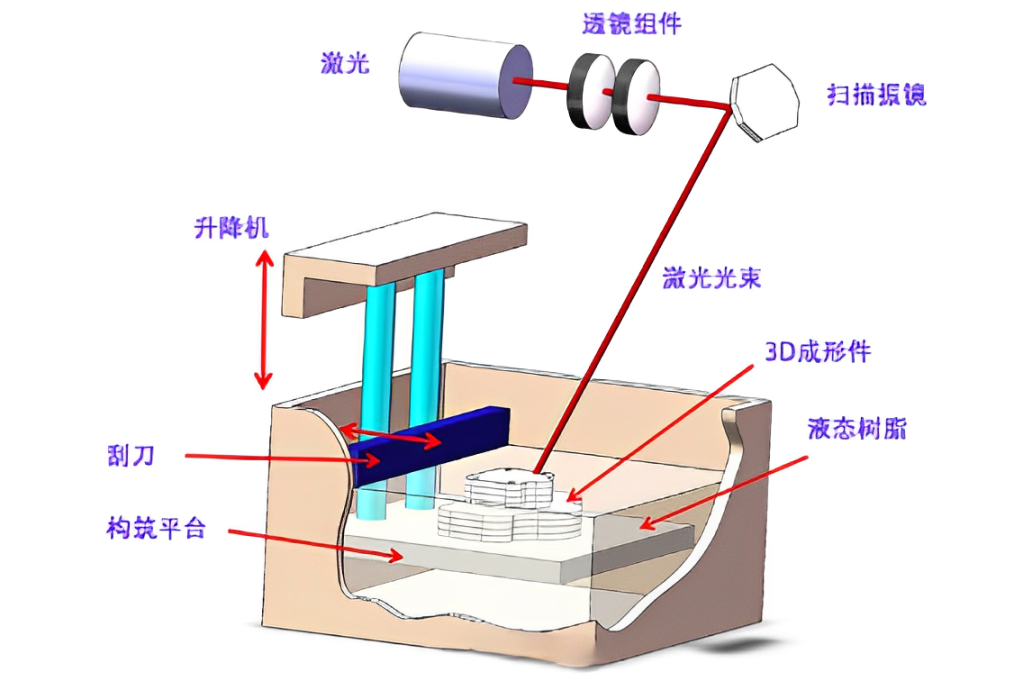

– Objet invented a new way to 3D print using photo-curable materials without relying on a liquid vat and a laser (a leading technique at the time)。 Objet’s innovative techniques made it possible to print with multiple materials.

– Arcam invented EBeam selective sintering to avoid using lasers to fuse powder into layers. The result is a faster printing process and objects with improved material properties.

– Optomec developed a printing process that sprays metal powder into the path of a laser beam. This novel technique avoids the use of a powder-bed, which opened the door to one of the most promising applications for 3D printing, the fabrication of precisely graded metal alloys

Today, these rival printing technologies benefit users and provide a rich foundation for future inventors, from both commercial and open-source worlds, to build upon. Patents can advance technological innovation because they force inventors to devise new workarounds.

So, returning to the hypothetical 3D-printing party, what problems do people have with 3D printing and patents? If key patents introduce constraints that force technological innovation, why does the controversy over 3D-printing patents continue?

It continues because the debate over the impact of patents seems to be scrambling together two different forms of advancement: technological advancement and a company‘s ability to launch new commercial printing products.

Commercial advancement, expiring patents and consumer printers

Let’s back up here for a minute and explain one of the hottest patent debates going on in the 3D-printing industry today: the impact of expired patents. The year 2009 marked the expiration date of technology patents for a key printing technology called FDM (invented by Scott Crump in 1989 and formerly owned by Stratasys)。 FDM is the technology behind the classic layer-by-layer extrusion of a thin plastic stream of material into a 3D pattern, a simple, low-cost technique ideal for consumer machines.

People who view patents as innovation-killers attribute 3D printing‘s recent growth surge to the expiration of FDM patents. Just a few years after the constraints imposed by FDM patents were lifted, today there are an estimated 100-plus different, low-cost 3D-printer models for sale (most notably MakerBot) that utilize FDM technology. A corresponding number of young companies sell these new consumer 3D printers or are raising funds on Kickstarter to develop their business plans.

One of our favorite intellectual property bloggers, Mike Masnick, put it this way: “Development and innovation [have] been held up for the last couple decades … not because the technology wasn’t available, but because of key patents that are apparently needed to build 3D printers.” [10 Amazing 3D-Printing Startups]

It‘s a compelling argument. But there’s a subtle point that‘s being missed in all the heat and noise: The impact of patents on the advancement of 3D-printing technologies is not monolithic. Patents trigger innovation by imposing constraints that force workarounds. These same patents stifle, or at least complicate, the introduction of new commercial products, as evidenced by the expiration of FDM patents and the ensuing landslide of new printers that followed.

In fact, when patents expire, the ensuing products that appear on the market are not necessarily innovative, at least from a technological perspective. Despite the launch of more than 100 commercial 3D printers in the last two years, most of these printers’ core technology is FDM, which dates back to the 1980s. If core patents truly blocked technological innovation, these new consumer-scale 3D-printer models on the market should represent a rich bazaar of ingenious new variations and additions that springboard off of old FDM technology.

Open-source hardware

To add another data point to the debate, there‘s the case of two early open-source 3D printers launched in 2006: RepRap (created by Adrian Bowyer and his team) and Fab@Home (created by Evan Malone and this article’s co-author Hod Lipson)。 Both systems were simple, do-it-yourself affairs. And, both Fab@home and RepRap were open source, meaning that their machine blueprints were freely available on the Web where anyone could download them.

Thousands of users downloaded these design blueprints and built their own 3D printers at home. Both projects encouraged technological innovation beyond the original blueprints. Several years later, MakerBot‘s early, commercial 3D printer would borrow many design elements from RepRap and Fab@Home.

After their launch in the mid-2000s, RepRap and Fab@home thrived for years, long before FDM patents expired in 2009. The presence of blocking patents did not discourage do-it-yourselfers from creating innovative new technologies on top of the core, open-sourced machine blueprints. However, and this is the heart of a fine and critical distinction, the presence of blocking patents had a different effect: In the case of open-sourced printers, patents acted as a commercial, not technological, constraint. Users could not necessarily turn their innovations into commercial products without first understanding and skillfully navigating the patent landscape. The Formlabs case is a good example of just how legally complicated the intertwined tangle of patents around a particular printing platform can get.

When patents go bad: blocking the bad ones

Patents force companies and innovators down different paths. Some companies create ways to invent around the barrier. Others tinker with open-sourced versions of the patented technology. Commercially minded users and companies must wait until a key patent expires before they can take advantage of the now-freely available technology; however, they don’t necessarily continue to innovate on top of it.

Patents aren‘t necessarily bad for innovation, even patents on a core technology. However, bad patents do exist. Some companies try to patent a technology or method that’s painfully obvious, that is already in broad use or that someone else has already invented. These are patents worth fighting.

Thanks to recent changes in patent law under the American Invents Act, there‘s a way to prevent the issuance of such patents. With help from 3D-printing experts and researchers, the Electronic Frontier Foundation and Harvard’s Cyberlaw Clinic have devised an admirable approach to block bad patents — they collect evidence of prior art and submit it to the U.S. Patent Office. The groups have already blocked six patent applications this way.

Going forward, the issue of patents will continue to sow dissent in the 3D-printing community. Intellectual property issues tap into people‘s core ideologies about appropriate degrees of private ownership and the placement of the boundary between intellectual commons and private commercial interests. In addition, intellectual property laws unfortunately can (and will) be misused and abused by unethical companies and individuals. We hope that as 3D printing continues to develop commercially, the black-and-white debate over the value of patents will embrace gradations of grey and aim its energy at legally preventing the issuance of bad patents on technologies that already exist.

自動翻譯僅供參考

為什么專利壁壘不會扼殺3D打印創新-生產制造設計

梅爾巴Kurman,作者和利普森,機械和航空航天工程康奈爾大學副教授,是“捏造:新世界的3D印刷”的合著者(約翰·威利父子,2013年)在3D領域,最主要的聲音打印。他們貢獻了這篇文章,以生活科學的專家聲音:專欄文章與觀點作為自己的新生活科學系列突出了3D打印技術問題和發展的一部分。

如果你想在一個充滿激情的3D打印派對上開始戰斗,那就提一下技術專利吧。立刻,人們會把他們的位置拋在一邊,房間就會陷入混亂。博主保羅?班瓦特把這場辯論概括為“那些認為專利阻礙了3D打印技術的人與那些認為專利真的激勵創新的人”之間的僵局。

專利是喜歡的人。一些做好事,努力幫助別人。其他專利的行為就像貪婪的官僚所躲在規章制度和湊向前前進的道路。只是要清楚的在這里,在這篇文章中,我們不是在談論尚未解決的,迫在眉睫的爭奪盜版或三維打印的IP(知識產權)保護設計的未經授權的拷貝。我們的意思是在被提出的公司,制造和銷售3D打印機及相關技術,實際的3D打印流程,工具和材料的專利。

約束驅動創新

專利推動技術進步,而不是像大多數人認為。傳統觀點認為,暫時的壟斷專利給公司,可允許企業重新政變的早期投資研究與發展(R&D)和所產生的專利律師費。當涉及到3D印刷技術,傳統智慧告訴只是故事的一小部分。 [創建者3D打印10個最古怪的事情]

專利有助于三維印刷技術的進步,但不是通過給出專利持有者暫時控制在特定的印刷技術。專利,關鍵平臺技術,特別是核心專利,有推3D打印技術向前發展,通過引入約束。專利引起的制約力科技別出心裁 - 這反過來,推動創新。今天幾個不同的3D印刷技術存在的原因是,在某種程度上,通過專利的封鎖關鍵技術,因此施加的限制需要建立解決方法。

技術綠色田野廣闊,開放的廣闊是好的。但是,隨著亞馬遜CEO杰夫·貝索斯所說的那樣,“節儉推動創新,就像其他的限制做的。其中的唯一途徑擺脫緊張的盒子就是去創造你的出路。”貝佐斯指的是亞馬遜的早期現金匱乏的日子,缺乏脂肪的廣告預算,該公司圍繞創新的制約因素,并最終創造了改變游戲規則的聯營計劃。

一些創新的3D打印技術是專利引起的約束水果。在過去的幾十年中,對商業戰場上發揮,3D印刷公司被迫拿出技術解決方法來發展自己的商用3D打印機及相關產品。為了避免專利訴訟,三維印刷企業約其他公司的技術專利發明創新的路上出了“緊盒子”。由于對手公司駕駛自己的方式圍繞專利引起的約束,他們發明了更多的創新技術。

在約束面對創新

在這種環境下,幾乎兩打新的和重要的三維打印技術的發明為直接或間接回應別人的專利。 [十大發明改變了世界]

下面是幾個例子:

- Objet公司采用光固化材料,而不依賴于液體的增值稅和激光(當時的領先技術)發明了一種新的方式來3D打印。 Objet公司創新的技術使人們有可能用打印多種材料。

- 雅駿發明了電子束選擇性燒結避免使用激光熔化粉末成層。其結果是更快打印過程和具有改進的材料性能對象。

- Optomec開發在打印過程中噴射金屬粉末進入的激光束的路徑。這種新穎的技術避免使用粉末床,打開門,以最有前途的應用三維打印技術之一,正是分級金屬合金的制造

如今,這些對手印刷技術中受益的用戶,并為未來的發明人提供了豐富的基礎上,從商業和開源的世界,為建立在。專利可以推動技術創新,因為他們迫使發明家設計出新的解決方法。

所以,回到假設的3D印刷方,有什么問題就人與3D打印和專利?如果關鍵專利引進,迫使技術創新的限制,為什么爭論的3D打印專利繼續嗎?

它繼續因為隨著專利影響的辯論似乎是兩種不同形式的進步對爭先恐后在一起:技術進步和公司推出新的商業印刷產品的能力。

商業進步,專利到期和消費類打印機

讓我們備份這里一分鐘,并解釋最熱門的專利之一,今天辯論將在3D印刷業:專利到期的影響。 2009年是(1989年由斯科特·克倫普發明與Stratasys公司以前擁有)技術專利的到期日期名為FDM的一個關鍵的印刷技術。 FDM是后面的經典層 - 層擠出材料的薄塑料流成三維圖案,一個簡單的,低成本的技術非常適用于消費機的技術。

人們誰查看專利的創新殺手屬性3D打印最近經濟飆升至FDM專利到期。通過FDM專利施加的限制被取消短短幾年后,今天估計有100多個不同的,低成本的3D打印機,利用FDM技術的機型出售(最明顯的是MakerBot)。年輕的公司相應數量的銷售這些新的消費者對3D打印機或正在籌集資金Kickstarter上發展自己的商業計劃。

我們最喜歡的知識產權博客,麥克Masnick,這樣說:“發展與創新[有]被擱置在過去的幾十年里。。.因為關鍵專利,不是因為技術是不可用的,但顯然需要的打造3D打印機。“ [10驚人的3D打印創業]

這是一個令人信服的理由。但有是一個的被錯過在所有的熱量和噪音一個微妙的一點:專利對3D打印技術進步的影響也不是鐵板一塊。專利通過強加的解決方法強行限制引發的創新。這些相同的專利扼殺,或者至少是復雜的,引進新的商業產品,就證明了FDM專利到期以及隨之而來的新的打印機隨之而來的山體滑坡。

事實上,當專利到期,即出現在市場上的隨后的產品不一定創新,至少從技術角度。盡管在過去兩年推出的100多個商用3D打印機,大多數這些打印機的核心技術是FDM,其歷史可以追溯到20世紀80年代。如果核心專利真正阻止技術創新,在市場上,這些新的消費級3D打印機型號應該代表的巧妙的新變化和增加跳板關閉舊FDM技術豐富的集市。

開源硬件

另一個數據添加到辯論中,有在2006年推出了兩款早期的開源3D打印機的情況:的RepRap和Fab @ Home的(由阿德里安·鮑耶和他的團隊創建)(埃文 - 馬龍和這篇文章的共同作者霍德創建李碧菁)。這兩個系統是簡單的,做它自己的事務。而且,無論是晶圓廠@家里的RepRap是開源的,這意味著他們的機器藍圖是免費提供的網站上,任何人都可以下載它們。

數以千計的用戶下載了這些設計藍圖,并建立了自己的3D打印機在家里。這兩個項目鼓勵技術創新超越了原來的藍圖。幾年后,MakerBot的早期,商用3D打印機將借用的RepRap和Fab @ Home的很多設計元素。

他們在2000年代中期推出后,的RepRap和Fab @ home的蓬勃發展多年,在2009年之前很久FDM專利過期阻礙專利并沒有建立在核心之上創新的新技術鼓勵做自己動手的存在,開源機器藍圖。然而,這是一個很好的和關鍵的區別的心臟,阻斷專利的存在產生了不同的影響:在開源打印機的情況下,專利充當商業,不是技術,約束。用戶可以不必把他們的創新成果轉化為商品,而不先理解和熟練導航專利態勢。該Formlabs情況是多么復雜的法律專利圍繞一個特定的打印平臺交織糾結可以得到一個很好的例子。

當專利變壞:阻止壞的

專利迫使企業和創新上下不同的路徑。有些公司創造的方式來創造周圍的屏障。其他鼓搗專利技術的開源版本。商業頭腦的用戶和企業必須要等到一個關鍵的專利過期前,他們可以采取現在,免費提供技術的優勢;然而,它們不一定繼續創新在它的上面。

專利并不一定是壞事創新,在核心技術,即使專利。然而,壞的專利確實存在。一些公司試圖申請專利技術或方法,這是非常明顯,那就是已經在廣泛使用或者別人已經發明了。這些都是值得的專利戰。

由于在美國發明法最近的變化在專利法中,有一種方法,以防止發行此類專利。與3D印刷專家和研究人員的幫助下,電子前沿基金會和哈佛大學的網絡法律診所已設計出了令人欽佩的方式來阻止壞的專利 - 他們收集現有的證據,并提交給美國專利局。該團體已經封鎖6專利申請這種方式。

展望未來,專利問題將繼續播種持不同政見者在3D打印界。知識產權問題挖掘到大約相應的學位私有制和安置知識產權公共和私人商業利益之間的邊界人民的核心思想。此外,知識產權法遺憾的是(將)被濫用和不道德的公司和個人濫用。我們希望,作為3D打印的不斷商業化開發,黑與白的爭論專利的價值將迎來灰度等級,并在法律上防止對已經存在的技術的發行不好的專利瞄準它的能量。

-

3D打印

+關注

關注

26文章

3562瀏覽量

109604

發布評論請先 登錄

相關推薦

高分子微納米功能復合材料3D打印加工介紹

3D打印技術,推動手板打樣從概念到成品的高效轉化

有源晶振在3D打印機應用方案

DMD芯片在3D打印中的創新應用

3D打印技術應用的未來

維愛普3D打印設備工字電感磁芯:驅動創新與高效的科技核心

3D打印汽車零部件建模設計3D打印服務

為什么專利壁壘不會扼殺3D打印創新

為什么專利壁壘不會扼殺3D打印創新

評論